Ngophuhliso olukhawulezayo lweibhetri ye-lithiumkushishino, iimeko zokusetyenziswa kweebhetri ze-lithium ziyaqhubeka nokwandisa kwaye zibe sisixhobo samandla esiyimfuneko kubomi kunye nomsebenzi wabantu.Xa kuziwa kwinkqubo yokuvelisa abenzi bebhetri ye-lithium, inkqubo yokuvelisa ibhetri ye-lithium ikakhulu ibandakanya izithako, ukugquma, ukubeka, ukulungiswa, ukugoqa, ukugoqa, ukuqengqeleka, ukubhaka, inaliti yolwelo, i-welding, njl. inkqubo yokuvelisa ibhetri ye-lithium.Izithako ze-electrode ezintle I-electrode efanelekileyo yeebhetri ze-lithium yenziwe ngezinto ezisebenzayo, i-conductive agents, i-adhesives, njl. Okokuqala, izinto eziluhlaza ziqinisekisiwe kwaye zibhaka.Ngokuqhelekileyo, i-agent ye-conductive kufuneka ibhakwe kwi-≈120℃ ngeeyure ze-8, kunye ne-PVDF enamathelayo kufuneka ibhakwe kwi-≈80℃ iiyure ze-8.Ingaba izinto ezisebenzayo (i-LFP, i-NCM, njl.) zifuna ukubhaka kunye nokomisa kuxhomekeke kwimeko yezinto eziluhlaza.Okwangoku, i-workshop yebhetri ye-lithium jikelele idinga ukushisa ≤40℃ kunye nomswakama ≤25%RH.Emva kokugqitywa kokumisa, iglue ye-PVDF (i-solvent ye-PVDF, isisombululo se-NMP) kufuneka ilungiswe kwangaphambili.Umgangatho weglue wePVDF ubalulekile ekuchaseni kwangaphakathi kunye nokusebenza kombane webhetri.Izinto ezichaphazela ukusetyenziswa kweglue ziquka ubushushu kunye nesantya esishukumisayo.Ukuphakama kweqondo lokushisa, i-yellowing yeglue iya kuchaphazela ukunamathela.Ukuba isantya sokuxuba sikhawuleza, iglue inokonakala lula.Isantya esikhethekileyo sokujikeleza sixhomekeke kubungakanani bediski yokusasazeka.Ngokuqhelekileyo, isantya somgca wediski ye-dispersion yi-10-15m / s (kuxhomekeke kwisixhobo).Ngeli xesha, itanki yokuxuba iyadingeka ukuvula amanzi ajikelezayo, kwaye izinga lokushisa kufuneka libe ngu-≤30 ° C.

Yongeza i-cathode slurry kwiibhetshi.Ngeli xesha, kufuneka ubeke ingqalelo kumyalelo wokongeza izinto.Okokuqala yongeza izinto ezisebenzayo kunye ne-agent eqhubayo, ugxobhoze ngokukhawuleza, uze udibanise iglue.Ixesha lokutya kunye nomlinganiselo wokutyisa kufuneka kwakhona uphunyezwe ngokungqongqo ngokwenkqubo yokuvelisa ibhetri ye-lithium.Okwesibini, isantya sokujikeleza kunye nesantya sokujikeleza kwesixhobo kufuneka silawulwe ngokungqongqo.Ngokubanzi, isantya somgca wokusasazwa kufuneka sibe ngaphezulu kwe-17m/s.Oku kuxhomekeke ekusebenzeni kwesixhobo.Abavelisi abahlukeneyo bahluka kakhulu.Kwakhona lawula i-vacuum kunye nobushushu bokuxuba.Kule nqanaba, ubukhulu be-particle size kunye ne-viscosity ye-slurry kufuneka ibonwe rhoqo.Ubungakanani be-particle kunye ne-viscosity zihambelana ngokusondeleyo nomxholo oqinileyo, iipropati eziphathekayo, ulandelelwano lokutya kunye nenkqubo yokuvelisa ibhetri ye-lithium.Ngeli xesha, inkqubo eqhelekileyo idinga ubushushu ≤30℃, ukufuma ≤25%RH, kunye ne-vacuum degree ≤-0.085mpa.Dlulisa i-slurry kwitanki yokudlulisa okanye ivenkile yepeyinti.Emva kokuba i-slurry idluliselwe ngaphandle, kufuneka ihlolwe.Injongo kukucoca amasuntswana amakhulu, ukucotha kunye nokususa i-ferromagnetic kunye nezinye izinto.Amasuntswana amakhulu aya kuchaphazela i-coating kwaye anokubangela ukukhutshwa ngokweqile kwebhetri okanye umngcipheko wesiphaluka esifutshane;imathiriyeli ye-ferromagnetic eninzi eludaka inokubangela ukuzikhupha kakhulu kwebhetri kunye nezinye iziphene.Iimfuno zenkqubo yale nkqubo yokuvelisa ibhetri ye-lithium zezi: ukushisa ≤ 40 ° C, umswakama ≤ 25% RH, ubukhulu be-mesh yesikrini ≤ 100 mesh, kunye nobukhulu be-particle ≤ 15um.

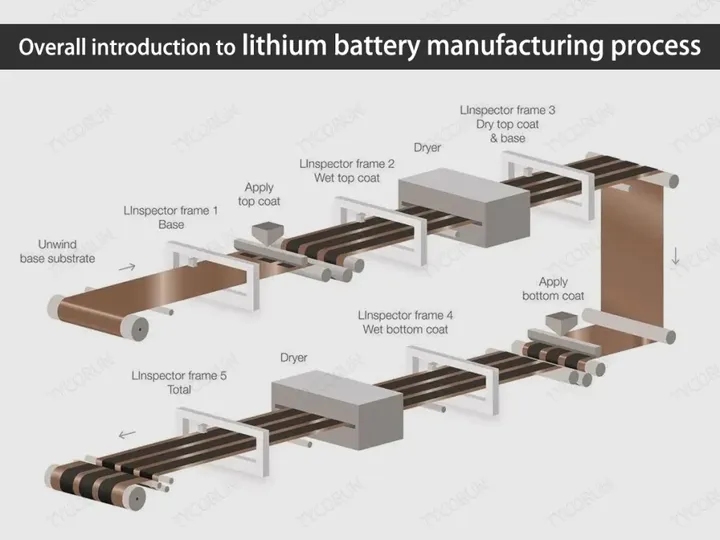

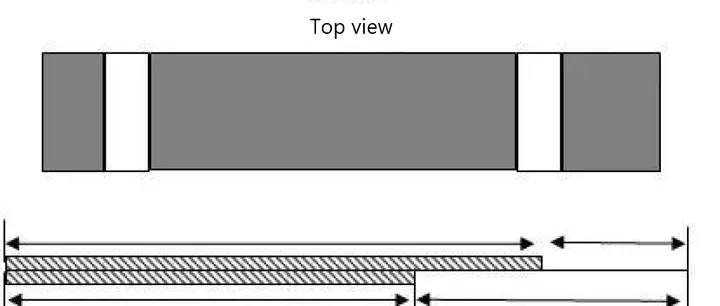

I-electrode engalungangaizithako I-electrode engalunganga yebhetri ye-lithium yenziwe ngezinto ezisebenzayo, i-agent eqhubayo, i-binder kunye ne-dispersant.Okokuqala, qinisekisa imathiriyeli ekrwada.Inkqubo ye-anode yendabuko yinkqubo yokuxuba okusekelwe kumanzi (i-solvent yi-deionized water), ngoko ke akukho mfuneko zokomisa ezikhethekileyo kwizinto eziluhlaza.Inkqubo yokuvelisa ibhetri ye-lithium idinga ukuba i-conductivity yamanzi e-deionized ibe ≤1us / cm.Iimfuno zeworkshop: ubushushu ≤40℃, ukufuma ≤25%RH.Lungisa iglu.Emva kokuba izinto eziluhlaza zichongiwe, iglue (eyenziwe ngeCMC kunye namanzi) kufuneka ilungiswe kuqala.Ngeli xesha, uthele i-graphite C kunye ne-agent eqhubayo kwi-mixer yokuxuba okomileyo.Kunconywa ukuba ungacoci okanye uvule amanzi ajikelezayo, kuba iinqununu zikhutshwe, zixutywe kwaye zifudumale ngexesha lokuxuba okomileyo.Isantya sokujikeleza sisantya esiphantsi 15 ~ 20rpm, umjikelezo wokukrala kunye nokugaya ngamaxesha angama-2-3, kwaye ixesha lekhefu li-≈15min.Galela iglu kwi-mixer kwaye uqale ukucoca (≤-0.09mpa).Gcoba irabha ngesantya esiphantsi se-15 ~ 20rpm ngamaxesha angama-2, emva koko ulungelelanise isantya (isantya esiphantsi 35rpm, isantya esiphezulu 1200 ~ 1500rpm), kwaye uqhube malunga ne-15min ~ 60min ngokwenkqubo emanzi yomenzi ngamnye.Ekugqibeleni, galela i-SBR kwi-blender.Ukushukumisa isantya esisezantsi kuyacetyiswa njengoko i-SBR iyipolymer yekhonkco elide.Ukuba isantya sokujikeleza sikhawuleza ixesha elide, ikhonkco le-molecular liya kuphuka ngokulula kwaye lilahlekelwe ngumsebenzi.Kunconywa ukuba uqhube ngesantya esiphantsi se-35-40rpm kunye nesantya esiphezulu se-1200-1800rpm imizuzu eyi-10-20.Uvavanyo lwe-viscosity (2000 ~ 4000 mPa.s), ubukhulu be-particle (35um≤), umxholo oqinileyo (40-70%), i-vacuum degree kunye ne-screen mesh (≤100 mesh).Amaxabiso enkqubo ethile aya kuhluka ngokuxhomekeka kwiimpawu ezibonakalayo zezinto kunye nenkqubo yokuxuba.Iworkshop ifuna ubushushu ≤30℃ kunye nokufuma ≤25%RH.Ukugquma i-cathode yokugquma Inkqubo yokuvelisa ibhetri ye-lithium ibhekisela ekukhupheni okanye ukutshiza i-cathode slurry kwi-AB surface yomqokeleli wangoku we-aluminium, kunye nobuninzi bomhlaba omnye ≈20 ~ 40 mg / cm2 (uhlobo lwebhetri ye-lithium ye-ternary).Ubushushu besithando somlilo ngokuqhelekileyo bungaphezu kwama-4 ukuya kwi-8 knots, kwaye ubushushu bokubhaka becandelo ngalinye buhlengahlengiswa phakathi kwe-95 ° C kunye ne-120 ° C ngokweemfuno zangempela zokuthintela ukuqhekeka okunqamlezayo kunye ne-solvent dripping ngexesha lokubhaka.Umlinganiselo wokugqithiswa kwesantya se-coating roller yi-1.1-1.2, kwaye indawo ye-gap iyancipha nge-20-30um ukuphepha ukuxinwa ngokugqithiseleyo kwendawo yeleyibhile ngenxa yomsila ngexesha lokuhamba ngebhayisikile, enokuthi ikhokelele kwimvula ye-lithium.Ukugquma umswakama ≤2000-3000ppm (kuxhomekeke kwizinto eziphathekayo kunye nenkqubo).Ukushisa kwe-electrode efanelekileyo kwi-workshop ngu-≤30℃ kunye nomswakama ngu-≤25%.Umzobo weskim ngolu hlobo lulandelayo: Umzobo weskimu wetape yokwambathisa

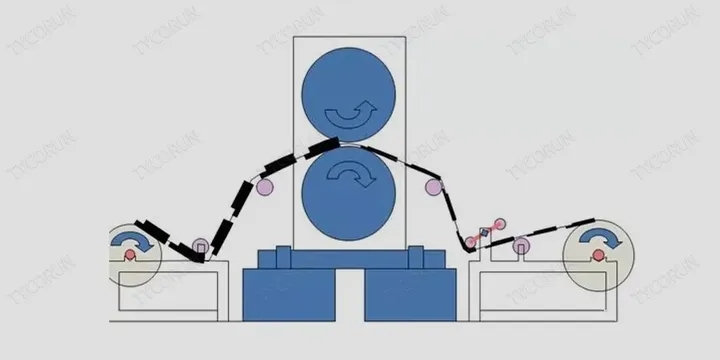

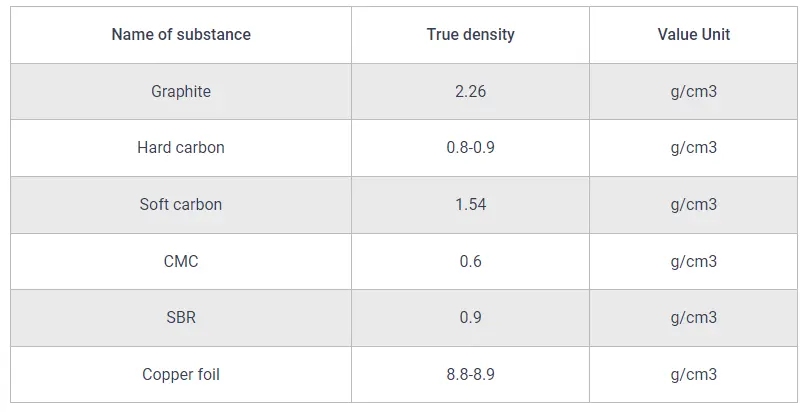

Iukwenziwa kwebhetri ye-lithiuminkqubo yeUkugquma kwe-electrode engalungangaibhekisa ekukhupheni okanye ekutshizeni udaka olubi lwe-electrode kumphezulu we-AB womqokeleli wangoku wobhedu.Ubuninzi bomhlaba omnye ≈ 10 ~ 15 mg / cm2.Ubushushu beziko lomlilo bunamacandelo ama-4-8 (okanye ngaphezulu), kwaye ubushushu bokubhaka becandelo ngalinye yi-80℃~105℃.Iyakwazi ukulungelelaniswa ngokweemfuno zangempela ukuphepha ukuqhekeka kokubhaka kunye nokuqhekeka okunqamlezayo.Umlinganiselo wesantya sokudlulisa i-roller yi-1.2-1.3, i-gap iyancipha i-10-15um, i-concentration yepeyinti i-≤3000ppm, iqondo lokushisa elibi le-electrode kwi-workshop ngu-≤30℃, kunye nomswakama ngu-≤25%.Emva kokuba i-coating ye-positive plate yomile, i-drum idinga ukulungelelaniswa ngaphakathi kwexesha lenkqubo.I-roller isetyenziselwa ukudibanisa ishidi le-electrode (ubunzima bokugqoka kwiyunithi yomthamo).Okwangoku, zimbini iindlela zokucinezela i-electrode elungileyo kwinkqubo yokwenziwa kwebhetri ye-lithium: ukucinezela okushushu kunye nokucinezela okubandayo.Xa kuthelekiswa nokucofa okubandayo, ukucinezela okushushu kunoxinzelelo oluphezulu kunye nesantya esisezantsi sokubuyela kwakhona.Nangona kunjalo, inkqubo yokucinezela okubandayo ilula kwaye kulula ukuyisebenzisa nokulawula.Isixhobo esiphambili se-roller kukufezekisa amaxabiso alandelayo enkqubo, ukuxinana kwe-compaction, i-rebound rate kunye nokwandisa.Ngexesha elifanayo, kufuneka kuqatshelwe ukuba i-chips brittle chips, izibonda ezinzima, izinto eziwa phantsi, i-wavy edges, njl.Ngeli xesha, iqondo lobushushu kwindawo workshop: ≤23℃, ukufuma: ≤25%.Ubuninzi bokwenyani bezinto eziqhelekileyo zangoku:

Ukuxinana okuxhaphakileyo:

Ireyithi yokubuyela kwakhona: i-rebound jikelele 2-3 μm

Ukwandiswa: Iphepha le-electrode elihle lidla ngokuba ≈1.002

Emva kokuba umqulu we-electrode ofanelekileyo ugqityiwe, isinyathelo esilandelayo kukwahlula isiqwenga se-electrode yonke ibe yimichilo emincinci yobubanzi obufanayo (ehambelana nokuphakama kwebhetri).Xa uqhekeza, nikela ingqalelo kwi-burrs yesiqhekeza.Kuyimfuneko ukuba uhlolisise ngokubanzi iziqwenga zeepali kwii-burrs kwiindlela ze-X kunye ne-Y ngoncedo lwezixhobo ezimbini-dimensional.Inkqubo yobude be-burr yobude Y≤1/2 H ubukhulu be-diaphragm.Ubushushu bendawo yokusebenzela kufuneka bube ngu-≤23℃, kwaye indawo yombethe kufuneka ibe ngu-≤-30℃.Inkqubo yokwenziwa kwamaphepha e-electrode engalunganga ye-lithium battery negative electrode sheets iyafana naleyo yee-electrode ezintle, kodwa inkqubo yoyilo yahlukile.Ubushushu bendawo yokusebenzela kufuneka bube ngu ≤23℃ kwaye ukufuma kube ≤25%.Ubuninzi bokwenyani bezinto eziqhelekileyo ezimbi ze-electrode:

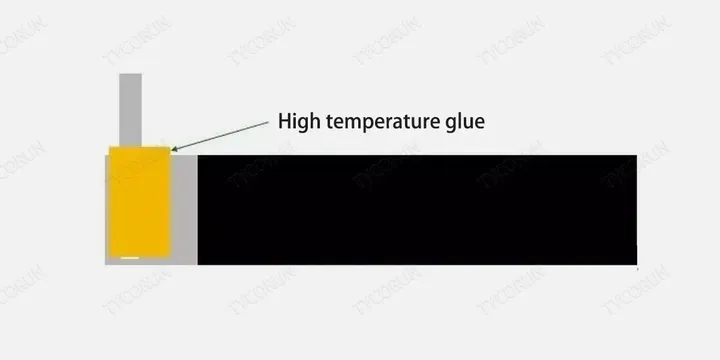

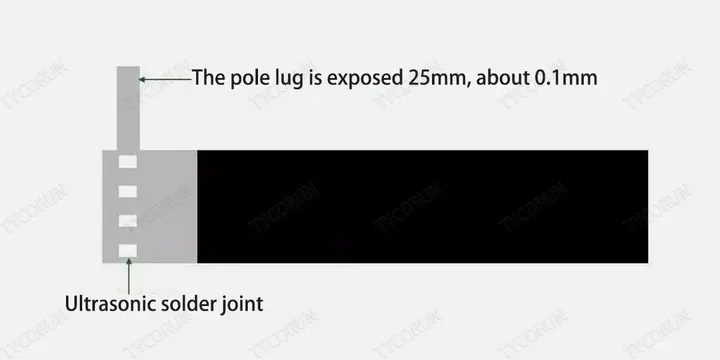

Ngokuqhelekileyo ukusetyenziswa kwe-electrode negative compaction: Izinga lokubuyela kwakhona: I-rebound jikelele 4-8um Elongation: Positive plate jikelele ≈ 1.002 Inkqubo yokuvelisa i-lithium ibhetri ye-electrode stripping ifana nenkqubo yokuhluthwa kwe-electrode encomekayo, kwaye zombini kufuneka zilawule i-burrs kwi-X kunye Y izalathiso.Ubushushu bendawo yokusebenzela kufuneka bube ngu-≤23℃, kwaye indawo yombethe kufuneka ibe ngu-≤-30℃.Emva kokuba ipleyiti ekhangayo ilungele ukuhluthwa, ipleyiti ekhangayo kufuneka yomiswe (120 ° C), emva koko i-aluminium sheet idityaniswe kwaye ihlanganiswe.Ngexesha lale nkqubo, ubude bethebhu kunye nobubanzi bokubumba kufuneka buqwalaselwe.Ukuthatha i-*650 uyilo (njengebhetri ye-18650) njengomzekelo, uyilo oluneethebhu eziveziweyo ikakhulu ukuqwalasela intsebenziswano efanelekileyo yeethebhu ze-cathode ngexesha le-cap kunye ne-roll groove welding.Ukuba iithebhu zepali zibonakaliswe ixesha elide, isiphaluka esifutshane sinokuvela ngokulula phakathi kweepali zeepali kunye negobolondo lensimbi ngexesha lokuqengqeleka.Ukuba i-lug imfutshane kakhulu, i-cap ayikwazi ukuthengiswa.Okwangoku, kukho iintlobo ezimbini zeentloko ze-ultrasonic welding: i-linear kunye ne-point-shaped.Iinkqubo zasekhaya ubukhulu becala zisebenzisa iintloko ze-welding ezihambelanayo ngenxa yoqwalaselo lwamandla agqithileyo kunye ne-welding.Ukongezelela, i-glue ephezulu yokushisa isetyenziselwa ukugubungela iithebhu ze-solder, ngokukodwa ukuphepha umngcipheko weesekethe ezimfutshane ezibangelwa i-burrs yensimbi kunye ne-debris yensimbi.Ubushushu bendawo yokusebenzela kufuneka bube ngu-≤23℃, indawo yombethe kufuneka ibe ngu-≤-30℃, kwaye umxholo wokufuma we-cathode kufuneka ube ngu-≤500-1000ppm.

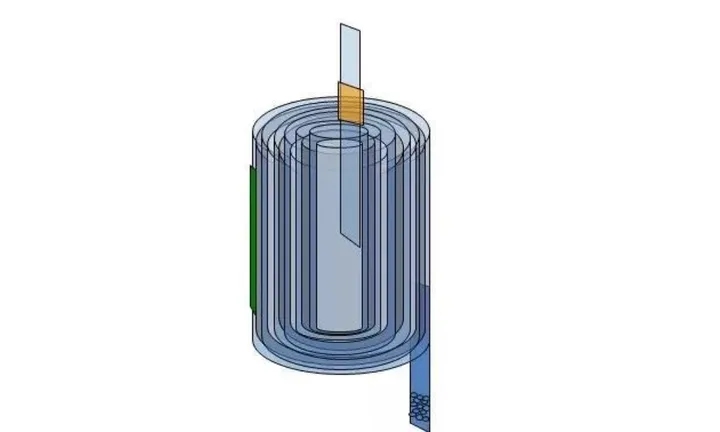

Ukulungiselela ipleyiti engalungangaIsitya esibi kufuneka some (105-110 ° C), emva koko amaphepha e-nickel ahlanganiswe kwaye ahlanganiswe.Ubude bethebhu ye-Solder kunye nobubanzi bokwenza kufuneka kuthathelwe ingqalelo.Ubushushu bendawo yokusebenzela kufuneka bube ngu-≤23℃, indawo yombethe kufuneka ibe ngu-≤-30℃, kwaye umxholo wokufuma we-electrode engalunganga kufuneka ibe ngu-≤500-1000ppm.Umoya kukuvuthuza isahluli, ishidi le-electrode eliqinisekileyo kunye neshiti ye-electrode engalunganga ibe ngumbindi wentsimbi ngomatshini wokujija.Umgaqo-siseko kukusonga i-electrode efanelekileyo kunye ne-electrode engalunganga, kwaye emva koko ukwahlula i-electrode echanekileyo kunye ne-negative ngokusebenzisa isahluli.Ekubeni i-electrode engalunganga yenkqubo yemveli yi-electrode yolawulo loyilo lwebhetri, uyilo lwamandla luphezulu kunolo lwe-electrode efanelekileyo, ukwenzela ukuba ngexesha lokutshaja, i-Li + ye-electrode efanelekileyo inokugcinwa "kwisithuba" se-electrode. i electrode negative.Ingqwalasela ekhethekileyo kufuneka ihlawulwe kuxinzelelo olujikelezayo kunye nelungiselelo leqhekeza lepali xa ujija.Uxinzelelo oluncinci kakhulu oluya kuchaphazela ukuchasana kwangaphakathi kunye nesantya sokufakwa kwezindlu.Ukuxinezeleka okugqithisileyo kunokukhokelela kumngcipheko wokujikeleza okufutshane okanye ukutshiphuza.Ukulungelelaniswa kubhekiselele kwindawo ehambelanayo ye-electrode engalunganga, i-electrode efanelekileyo, kunye ne-separator.Ububanzi be-electrode engalunganga ngu-59.5 mm, i-electrode efanelekileyo yi-58 mm, kunye ne-separator yi-61 mm.Ezi zintathu zilungelelaniswa ngexesha lokudlala ukuphepha umngcipheko weesekethe ezimfutshane.Uxinzelelo olujikelezayo luphakathi kwe-0.08-0.15Mpa kwipali echanekileyo, i-0.08-0.15Mpa ye-polegetive pole, i-0.08-0.15Mpa ye-diaphragm ephezulu, kunye ne-0.08-0.15Mpa ye-diaphragm engezantsi.Uhlengahlengiso oluthile luxhomekeke kwisixhobo kunye nenkqubo.Ubushushu be-ambient yale workshop ngu-≤23℃, indawo yombethe ngu-≤-30℃, kwaye umxholo wokufuma ngu-≤500-1000ppm.

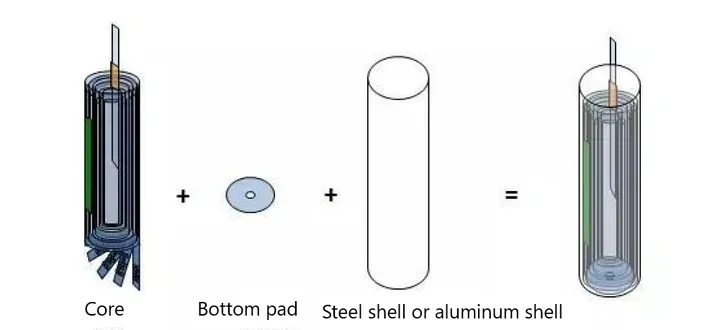

Ngaphambi kokuba undoqo webhetri ufakwe kwimeko, uvavanyo lwe-Hi-Pot lwe-200 ~ 500V luyafuneka (ukuvavanya ukuba ibhetri ye-high-voltage i-short-circuited), kunye ne-vacuuming nayo iyafuneka ukulawula uthuli ngaphambi kokuba ifakwe. ityala.Amanqaku amathathu amakhulu okulawula iibhetri ze-lithium ngumswakama, i-burrs kunye nothuli.Emva kokuba inkqubo yangaphambili igqityiwe, faka i-gasket esezantsi ezantsi kumbindi webhetri, ugobe iphepha le-electrode eliqinisekileyo ukuze umphezulu ujongane nombindi webhetri wepinhole, kwaye ekugqibeleni uyifake ngokuthe nkqo kwiqokobhe lentsimbi okanye iqokobhe le-aluminium.Ukuthatha uhlobo lwe-18650 njengomzekelo, ububanzi obungaphandle ≈ 18mm + ubude ≈ 71.5mm.Xa ummandla onqamlekileyo wecala lenxeba lincinci kunendawo yangaphakathi yecala lentsimbi, isantya sokufakwa kwentsimbi yentsimbi malunga ne-97% ukuya kwi-98.5%.Ngenxa yokuba ixabiso le-rebound ye-pole piece kunye neqondo lokungena kwamanzi ngexesha lokutofa kamva kufuneka lithathelwe ingqalelo.Inkqubo efanayo kunye ne-underlayment yomhlaba iquka ukuhlanganisana kwe-underlayment ephezulu.Ubushushu bendawo yokusebenzela kufuneka bube ngu-≤23℃, kwaye indawo yombethe kufuneka ibe ngu-≤-40℃.

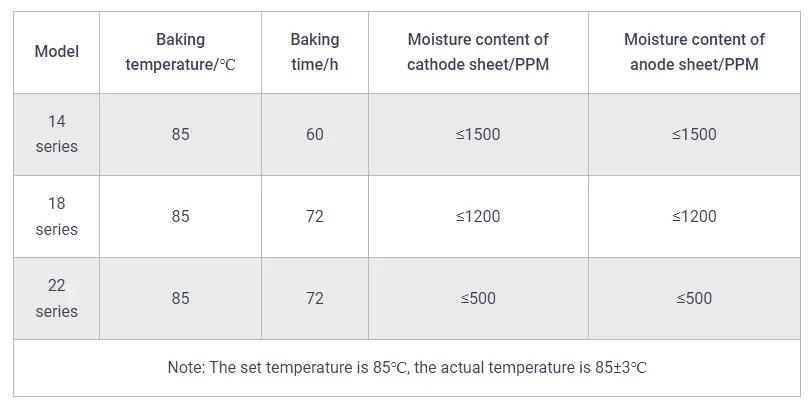

Ukuqengqelekaifaka ipini ye-solder (edla ngobhedu okanye i-alloy) embindini we-solder core.Izikhonkwane ze-welding ezisetyenziswa ngokuqhelekileyo ziyi-Φ2.5 * 1.6mm, kwaye amandla e-welding ye-electrode engafanelekiyo kufuneka abe ≥12N ukuba afaneleke.Ukuba iphantsi kakhulu, iya kubangela ngokulula i-soldering ebonakalayo kunye nokumelana okugqithisileyo kwangaphakathi.Ukuba iphezulu kakhulu, kulula ukuwelda umaleko we-nickel kumphezulu weqokobhe lentsimbi, okukhokelela kumalungu e-solder, okukhokelela kwiingozi ezifihlakeleyo ezinjengomhlwa kunye nokuvuza.Ukuqonda okulula kwe-groove kukulungisa i-core yebhetri yesilonda kwi-casing ngaphandle kokugubha.Kwinkqubo yokwenziwa kwebhetri ye-lithium, ingqwalasela ekhethekileyo kufuneka ihlawulwe ekufaniseni isantya sokugqithiswa kwe-extrusion kunye nesantya sokucinezela i-longitudinal ukuphepha ukusika i-casing kwisantya esiphezulu esinqamlezayo, kunye ne-nickel layer yenotshi iya kuwa ukuba isantya selongitudinal sikhawuleza kakhulu okanye ukuphakama kwenotshi kuya kuchaphazeleka kwaye ukutywinwa kuya kuchaphazeleka.Kuyimfuneko ukujonga ukuba amaxabiso enkqubo yobunzulu begroove, ukwandiswa kunye nokuphakama kwegroove kuhambelana nemigangatho (ngokubala okusebenzayo kunye nethiyori).Ubukhulu behob eziqhelekileyo ziyi-1.0, 1.2 kunye ne-1.5 mm.Emva kokuba i-groove eqengqelekayo igqityiwe, umatshini wonke kufuneka uhlanjululwe kwakhona ukuphepha i-debris yesinyithi.Idigri yevacuum kufuneka ibe ngu-≤-0.065Mpa, kwaye ixesha lokucoca kufuneka libe yi-1 ~ 2s.Iimfuno zobushushu be-ambient zale workshop zi-≤23℃, kwaye indawo yombethe yi-≤-40℃.Ukubhaka okungundoqo kwebhetri Emva kokuba amaqabunga ebhetri e-cylindrical agqitywe kwaye afakwe kwi-grooved, inkqubo elandelayo yokuvelisa ibhetri ye-lithium ibaluleke kakhulu: ukubhaka.Ngexesha lokuveliswa kweeseli zebhetri, umlinganiselo othile womswakama ungeniswa.Ukuba ukufuma akukwazi kulawulwa kuluhlu olusemgangathweni ngexesha, ukusebenza kunye nokhuseleko lwebhetri luya kuchaphazeleka kakhulu.Ngokuqhelekileyo, i-oven vacuum ezenzekelayo isetyenziselwa ukubhaka.Cwangcisa iiseli ukuba zibhakwe ngokucocekileyo, faka i-desiccant kwi-oven, ubeke iiparitha, kwaye uphakamise izinga lokushisa ukuya kuma-85 ° C (uthatha iibhetri ze-lithium iron phosphate njengomzekelo).Oku kulandelayo yimigangatho yokubhaka kwiinkcukacha ezininzi ezahlukeneyo zeeseli zebhetri:

Isitofu samanziInkqubo yokwenziwa kwebhetri ye-lithium ibandakanya ukuvavanywa kokufuma kweeseli zebhetri ezibhakiweyo.Kuphela emva kokufikelela kwimigangatho yokubhaka yangaphambili ungaqhubeka nesinyathelo esilandelayo: ukujova i-electrolyte.Ngokukhawuleza faka iibhetri ezibhakiweyo kwibhokisi yeglavu yevacuum, ulinganise kwaye urekhode ubunzima, beka ikomityi yokutofa, kwaye udibanise ubunzima obuyiliweyo be-electrolyte kwikomityi (ngokuqhelekileyo uvavanyo lwebhetri oluntywiliselweyo luyenziwa: faka ibhetri ekomityini. phakathi).Faka undoqo webhetri kwi-electrolyte, uyicwilise kangangexesha elithile, uvavanye umthamo omkhulu wokufunxa ulwelo lwebhetri (uhlala ugcwalisa ulwelo ngokwevolumu yovavanyo), uyibeke kwibhokisi yokucoca ukuze uthambise (iqondo lokufunxa ≤ - 0.09Mpa), kwaye ukhawulezise ukungena kwe-electrolyte kwi-electrode.Emva kwemijikelo emininzi, susa amaqhekeza ebhetri kwaye uwalinganise.Bala ukuba umthamo wenaliti uyahlangabezana nexabiso loyilo.Ukuba incinci, kufuneka izaliswe kwakhona.Ukuba kuninzi kakhulu, vele ukhuphe ukugqithisa de ube uhlangabezana neemfuno zoyilo.Indawo yebhokisi yeglavu ifuna ubushushu ≤23℃ kunye nendawo yombethe ≤-45℃.

UkuweldaNgexesha lenkqubo yokuvelisa ibhetri ye-lithium, isigqubuthelo sebhetri kufuneka sibekwe kwibhokisi yeglavu kwangaphambili, kwaye isigqubuthelo sebhetri kufuneka sigxininiswe kwi-mold ephantsi yomatshini we-welding ephezulu ngesandla esinye, kwaye isiseko sebhetri kufuneka sibanjwe ngesinye. isandla.Lungelelanisa ilugi elungileyo yeseli yebhetri kunye netheminali yelugi yekhava.Emva kokuqinisekisa ukuba i-terminal lug efanelekileyo ihambelana ne-cap terminal lug, nyathela kumatshini we-ultrasonic welding.Emva koko nyathela unyawo lomatshini wokuwelda.Emva koko, iyunithi yebhetri kufuneka ihlolwe ngokupheleleyo ukujonga umphumo we-welding yeethebhu ze-solder.

Jonga ukuba iithebhu ze-solder zilungelelanisiwe.

Tsala ngobunono kwithebhu ye-solder ukuze ubone ukuba ikhululekile.

Iibhetri ezinekhava yebhetri engadityaniswanga ngokuqinileyo kufuneka zidityaniswe ngokutsha.

Ixesha lokuposa: May-27-2024